Your packaging tells a story. It’s the first thing your customers see and feel when interacting with your brand. This first impression counts, especially in premium packaging, where aesthetics and tactile experiences are key to standing out. But when it comes to that luxurious, velvety finish, how do you decide between soft touch coating and soft touch lamination?

Let’s explore these two popular finishes, their differences, and when to use each one.

What Is Soft Touch Coating?

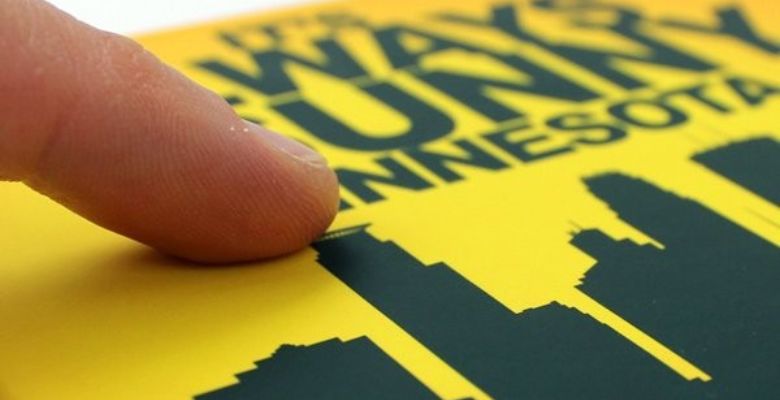

Soft touch coating is a post-printing finish that gives your packaging a smooth, velvety texture, instantly elevating its appeal. This finish is a favorite in many industries, from cosmetics to tech packaging, and for a good reason.

How is it applied?

Soft touch coating is sprayed or applied as a liquid onto printed materials. Once it dries, it forms a luxurious matte layer that’s soft to the touch.

Pros of Soft Touch Coating

- Inexpensive: Great for cost-effective projects.

- Aesthetic Appeal: Adds a high-end look with minimal effort.

- Soft Texture: Delivers a smooth, tactile experience that customers love.

Cons of Soft Touch Coating

- Less Durable: Coating can wear off with time, especially with frequent handling.

- Limited Moisture Protection: It doesn’t offer significant resistance against water or humidity.

Quick Tip: Use soft touch coating for short-term projects like promotional materials, where durability isn’t the primary concern.

What Is Soft Touch Lamination?

Soft touch lamination takes the tactile experience a step further by not only providing a soft, matte finish but also protecting your packaging. This process applies a plastic film over the printed material, adding both texture and durability.

How does it work?

A soft plastic film is laminated onto the packaging, giving it a velvety feel while enhancing its longevity.

Pros of Soft Touch Lamination

- High Durability: The lamination protects your packaging from wear and tear.

- Water and Tear Resistance: It adds a protective barrier that resists moisture and rough handling.

- Long-Lasting Tactile Experience: The soft texture remains intact even after extended use.

Cons of Soft Touch Lamination

- More Expensive: Due to the added material and process.

- Time-Consuming Application: It requires more production time compared to coating.

Pro Tip: Opt for soft touch lamination when durability is a priority, such as for packaging that will face frequent handling or exposure to moisture.

Key Differences Between Soft Touch Coating and Soft Touch Lamination

Both finishes offer a luxurious matte texture, but the differences lie in durability, cost, and application.

| Aspect | Soft Touch Coating | Soft Touch Lamination |

| Durability | Less durable, suited for short-term projects | Highly durable, suitable for long-term use |

| Cost | Cost-effective | More expensive |

| Application Method | Sprayed or applied as a liquid | Laminated with a plastic film |

Which should you choose?

- Budget-Friendly Needs: If you’re on a tight budget or working on a short-term project, soft touch coating is an ideal choice.

- Premium, Long-Lasting Packaging: For premium, long-lasting packaging, soft touch lamination offers unmatched durability and protection.

Read Also: A Comprehensive Guide to Aqueous Coating in Printing

When to Use Soft Touch Coating

Soft touch coating works best in situations where the tactile experience matters, but durability isn’t a major concern. If you’re creating short-term projects or marketing materials, such as:

- Brochures

- Business Cards

- Promotional Packaging

Coating can provide the desired luxury look without straining your budget. The soft feel will captivate customers, adding a high-end touch to your branding.

Question: Are you planning a marketing campaign that requires elegant, cost-effective packaging? Soft touch coating might be your perfect solution!

When to Use Soft Touch Lamination

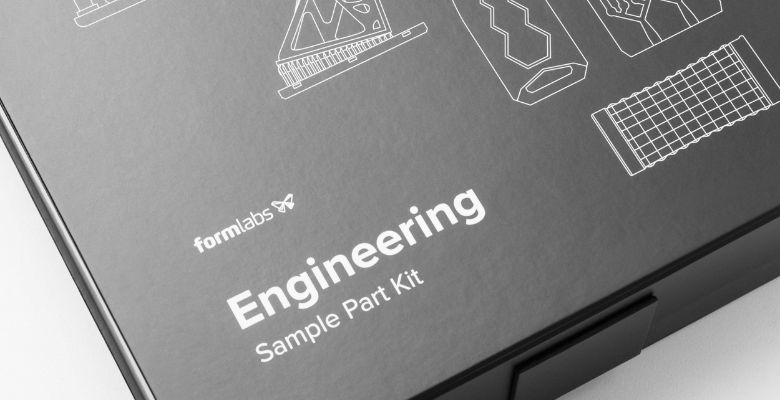

Soft touch lamination is the go-to choice for projects that require extra durability. Whether it’s luxury packaging or high-end retail boxes, lamination ensures your packaging looks and feels premium while standing up to wear and tear. Common uses include:

- Product Packaging (especially for high-end goods)

- Hardcover Books

- Luxury Cosmetic or Tech Packaging

Its added protection against moisture and scratches makes lamination ideal for packaging that will endure frequent handling or challenging conditions.

CTA: Need durable, premium packaging? Contact us today to explore how soft touch lamination can enhance your products!

Studies & Research

Studies have shown that tactile finishes like soft touch coatings or laminations can significantly enhance the perceived value of a product. Customers are more likely to associate soft, high-quality packaging with premium products, which can increase brand loyalty and encourage repeat purchases.

Additionally, durability studies comparing the lifespan of soft touch coating versus lamination indicate that lamination consistently outperforms coating in terms of longevity, especially in environments with high moisture levels or frequent handling.

Effect on Consumer Perception

- Enhanced Perceived Value: Tactile finishes make products appear more luxurious.

- Increased Brand Loyalty: High-quality packaging fosters trust and repeat business.

Durability Comparisons

- Soft Touch Coating: Suitable for short-term use with limited exposure to harsh conditions.

- Soft Touch Lamination: Ideal for long-term use, offering superior protection and resilience.

Conclusion: Which Is Right for You?

Deciding between soft touch coating and lamination boils down to budget and durability needs.

- Short-Term or Budget-Conscious Projects:

Soft touch coating can give you the luxurious finish you need without the high cost. It’s perfect for marketing materials and promotional items where the tactile experience enhances the customer’s interaction without requiring extensive durability. - Long-Term, Premium Packaging:

If protection and longevity are key, soft touch lamination is worth the investment. It ensures your packaging remains pristine, even with frequent handling or exposure to moisture, making it ideal for high-end products and durable goods.

Ready to elevate your packaging? Get in touch with us today to explore how soft touch finishes can add that premium touch to your products.

FAQ

Q: Is soft touch lamination worth the extra cost?

A: Yes, if your project requires added protection and long-term use. The durability and water resistance make it a great investment for premium packaging.

Q: Can I use both soft touch coating and lamination?

A: While both finishes provide a soft, matte feel, it’s unnecessary to use both. Choose the one that best suits your project’s needs.

Q: How does soft touch coating affect the printing quality?

A: Soft touch coating enhances the visual appeal by adding a matte finish without compromising the vibrancy of the printed colors.

Q: What industries benefit the most from soft touch finishes?

A: Industries like cosmetics, luxury goods, technology, and publishing benefit significantly from soft touch coatings and laminations due to the enhanced tactile experience they offer.

Interactive Elements

Poll: Which Soft Touch Finish Do You Prefer?

- Soft Touch Coating

- Soft Touch Lamination

- Not Sure Yet

Share Your Experience!

Have you used soft touch finishes in your packaging? Share your experiences and results in the comments below!

Make your packaging a tactile masterpiece—choose the right finish today!

By understanding the nuances between soft touch coating and soft touch lamination, you can make informed decisions that align with your brand’s vision and customer expectations. Whether you prioritize cost-efficiency or durability, both finishes offer unique advantages that can elevate your packaging to new heights.

Need Expert Guidance?

Our team of packaging specialists is here to help you select the perfect finish for your needs. Contact Us 99 designs packaging today to start your journey towards premium packaging!

Stay Connected

Follow us on LinkedIn, Facebook, and Instagram for the latest trends and tips in packaging design and finishes.