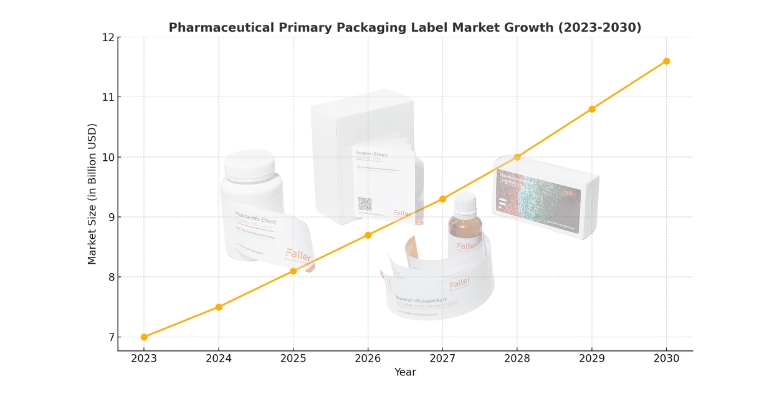

The pharmaceutical primary packaging label market is expected to grow significantly, with a projected annual growth rate (CAGR) of 7.20% by 2030. This growth highlights the increasing importance of labels in ensuring the safety, authenticity, and compliance of pharmaceutical products.

This article breaks down why the market is expanding, what primary packaging labels are, and how emerging trends and technologies are shaping the future of pharmaceutical labeling.

What Are Primary Packaging Labels in Pharmaceuticals?

Primary packaging labels are the labels applied directly to a product’s packaging, such as bottles, blister packs, syringes, and vials. These labels are critical for:

- Product Information: Including drug name, usage instructions, and expiry dates.

- Safety and Traceability: Using barcodes, QR codes, and RFID tags to prevent counterfeit drugs.

- Compliance: Meeting health authority regulations like the FDA and WHO.

- Branding: Enhancing brand visibility and recognition.

These labels play a vital role in both patient safety and supply chain efficiency.

What’s Driving the Growth in Pharmaceutical Labeling?

Several factors are contributing to the rapid growth of this market:

1. Tougher Regulations

Governments and health organizations demand more detailed labels to ensure product safety and patient trust. Non-compliance with regulations can lead to product recalls and penalties, pushing manufacturers to prioritize better labeling solutions.

2. Serialization and Track-and-Trace Technology

Fake drugs are a major concern in the pharmaceutical industry. Modern labels now include technologies like:

- Barcodes and QR codes to verify product authenticity.

- RFID tags for tracking products through the supply chain.

These innovations help combat counterfeit drugs and enhance patient safety.

3. Growth of Biopharmaceuticals

The rise of biopharmaceuticals and personalized medicine has created a demand for specialized labels that include precise dosing, storage conditions, and patient-specific information.

4. Advances in Printing Technology

Modern technologies like digital printing and smart labels make it easier to produce high-quality labels. These labels can withstand tough environments, such as extreme temperatures and moisture.

5. Patient-Friendly Packaging

Pharmaceutical companies are focusing on packaging that improves patient understanding. Clear and interactive labels, such as those with QR codes linking to instructional videos, are becoming more popular.

Market Segmentation: Breaking It Down

The market can be divided into key categories:

1. Materials Used

- Paper Labels: Cost-effective for general applications.

- Plastic Labels: Durable and ideal for extreme conditions.

- Sustainable Labels: Growing in demand due to environmental concerns.

2. Printing Technologies

- Digital Printing: Perfect for small, custom batches.

- Flexographic Printing: Cost-effective for large-scale production.

- Offset Printing: Known for its high-quality output.

3. Application Areas

- Injectables: Moisture-resistant labels for vials and ampoules.

- Oral Medications: Labels for blister packs and bottles.

- Topical Treatments: Durable labels for creams and gels.

4. Regions

- North America: Leading due to strict regulations and advanced technologies.

- Europe: Focused on eco-friendly and serialized labeling.

- Asia-Pacific: Growing rapidly with manufacturing hubs in India and China.

Trends Shaping the Future of Pharmaceutical Labeling

1. Smart Labels

Smart labels equipped with RFID and NFC (Near Field Communication) help track product conditions like temperature and humidity. They ensure drug quality throughout the supply chain.

2. Sustainability

With growing environmental awareness, manufacturers are using:

- Recyclable materials

- Water-based adhesives

- Biodegradable labels

This shift aligns with global efforts to reduce waste.

3. Digital Integration

Labels now often include QR codes or augmented reality (AR) features that link patients to instructional videos or product information. These interactive labels enhance patient engagement.

4. Anti-Counterfeit Features

Technologies like holograms and tamper-evident seals make it harder for counterfeiters to replicate genuine products.

5. Personalized Labels

Advanced printing techniques now allow for highly customized labels, tailored to individual patient needs, such as specific dosing instructions or allergen warnings.

Read More: How to Create and Print UPS Shipping Labels

Challenges Facing the Market

Despite its growth, the industry faces some challenges:

- High Costs: Advanced labels like RFID-enabled ones are expensive to produce.

- Regulatory Complexity: Different countries have varying labeling standards, which can complicate compliance.

- Counterfeiting Risks: As counterfeit methods evolve, constant innovation is needed to stay ahead.

Opportunities in the Market

For Manufacturers

By investing in advanced printing technologies and smart labels, manufacturers can offer premium services and stay competitive.

For Tech Providers

Companies offering track-and-trace systems or smart labeling technologies will see significant demand in the coming years.

For Regulators

Promoting uniform global standards can improve patient safety and facilitate smoother international trade.

Market Outlook: What to Expect by 2030

By 2030, the pharmaceutical primary packaging label market is expected to grow significantly due to:

- Increased adoption of smart labels.

- Expansion of sustainable materials for labels.

- Higher investment in digital printing technologies.

With a projected CAGR of 7.20%, the market shows no signs of slowing down.

Conclusion: The Future is Bright for Pharmaceutical Labels

The pharmaceutical primary packaging label market is evolving rapidly, driven by stricter regulations, technological advancements, and a growing focus on sustainability. As manufacturers, regulators, and tech providers adapt to these changes, the industry is set to thrive.

Labels are no longer just a compliance requirement—they are a vital part of ensuring patient safety, preventing counterfeiting, and improving the overall pharmaceutical supply chain. With the anticipated growth, stakeholders have immense opportunities to innovate and lead in this essential market.

Whether it’s through smart labeling, eco-friendly materials, or digital integration, the future of pharmaceutical labeling is more exciting than ever. By embracing these advancements, the industry is set to achieve remarkable progress, ensuring safety and quality for patients worldwide. Visit 99 designs packaging for more latest packaging insights.